10 in Table Saw With Wheeled Stand Model #rts31 Review

Best Portable Jobsite Tabular array Saw

One of the near widely used power tools for carpenters is the table saw. For carpenters that don't work exclusively in the shop a portable jobsite table saw is essential. For this Head-to-Head we're focusing on corded portable 10″ jobsite tabular array saws. We are not including cordless table saws in this test as we plan on doing another head-to-head exclusively for cordless table saws later this year as several are available at present.

Portable Table Saw Lineup

This portable jobsite table saw head-to-head includes 8 saws from; Bosch, Delta, DEWALT, Hitachi, Makita, Ridgid, SawStop and Skilsaw. Originally, we had as well to include Ryobi as a budget friendly choice for DIY'ers or guys just starting in the trades. However, we were not able to adapt that saw to our testing rigs so nosotros pulled information technology from the testing (you lot may encounter some photos with the saw but again we're not including it in the results).

- Bosch Model 4100-09 10 In. Worksite Tabular array Saw with Gravity-Rise™ Wheeled Stand

- Delta Model 36-6022 Portable Table Saw with Stand

- DEWALT Model DWE7491RS ten″ Jobsite Table Saw 32 – one/ii″ Rip Capacity, and a Rolling Stand up

- Hitachi Model C10RJ x″ Jobsite Table Saw west Fold Coil Stand

- Makita Model 2705X1 10" Contractor Tabular array Saw with Portable Stand

- Ridgid Model R4513 Heavy Duty 10 in. Portable Table Saw With Stand

- SawStop Model JSS-MCA Jobsite Table Saw

- Skilsaw Model SPT99-12 10″ Heavy Duty Worm Drive Table Saw

Table Saw Evaluation Format

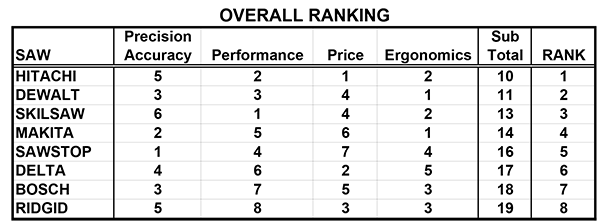

Over again our team has put some serious time and endeavour into our Head-to-Caput evaluation to bring you the about comprehensive data bachelor. For this evaluation, we broke things into several categories including: Precision & Accuracy, Operation (power), Price, and Ergonomics. For each of these categories we'll rank the saws and at the cease we'll proper noun the Best Portable Jobsite Table Saw based on all the results combined.

- Precision & Accuracy – In this category we evaluated the accurateness of the table saws straight out of the box, and how easy it is to brand scale adjustments. We also discuss the quality of the fence system as it relates to ripping accurate cuts.

- Operation – The performance evaluation took a very deep dive into the ability of the saw motors and how well the saws managed dissimilar ripping materials including plywood, force per unit area treated Southern Yellow Pino v/iv decking and Mahogany five/iv decking. We measured saw RPM's and Amps for each of the cutting materials under constant feed rates.

- Cost – Toll is e'er an important cistron in determining which saw is best for a user. Nosotros've included the current pricing found online for each of the saws at the fourth dimension of publication.

- Ergonomics – Ergonomics are really important to users and an important category to consider when purchasing any ability tool. In add-on to traditional ergonomics, we also included functionality in this category.

Portable Jobsite Table Saw Features

Earlier we present the testing results, information technology's helpful to set the phase by listing all the features and specifications for comparison. All eight of these jobsite table saws are similar in size and capacity. Each of the saws uses a x inch bract, 15 amp motor and they are all able to use a dado set up. Specific differences in the saws are listed beneath.

- Bosch 4100-09

- Weight: 112 lbs (w/ stand)

- MAX no Load Speed: iii,650 rpm

- Dept of Cut at ninety Deg.: 3-i/8″

- Depth of Cut at 45 Deg.: two-one/two″

- MAX Rip Cut to Right of Bract: 25″

- MAX Dado Cut Width: 13/16″

- Traditional sliding contend.

- Delta 36-6022

- Weight: 92 lbs (w/ stand)

- MAX no Load Speed: 5,000 rpm

- Dept of Cut at 90 Deg.: 3-1/ii″

- Depth of Cut at 45 Deg.: 2-1/2″

- MAX Rip Cut to Right of Bract: 30″

- MAX Dado Cut Width: 13/16″

- Traditional sliding fence

- DEWALT DWE7491RS

- Weight: 90 lbs (due west/ stand)

- MAX no Load Speed: 4,800 rpm

- Dept of Cutting at 90 Deg.: 3-i/8″

- Depth of Cut at 45 Deg.: 2-1/4″

- MAX Rip Cut to Right of Blade: 32-ane/2″

- MAX Dado Cut Width: 13/16″

- Rack and pinion debate

- Hitachi C10RJ

- Weight: 96 lbs (westward/ stand)

- MAX no Load Speed: 4,500 rpm

- Dept of Cut at 90 Deg.: 3-1/8″

- Depth of Cutting at 45 Deg.: 2-ane/four″

- MAX Rip Cut to Right of Blade: 35″

- MAX Dado Cutting Width: 13/16″

- Rack and pinion fence

- Makita 2705X1

- Weight: 114 lbs (w/ stand)

- MAX no Load Speed: 4,800 rpm

- Dept of Cut at 90 Deg.: 3-5/8″

- Depth of Cut at 45 Deg.: ii-1/two″

- MAX Rip Cut to Right of Blade: 25″

- MAX Dado Cutting Width: xiii/16″

- Traditional sliding fence

- Ridgid R4513

- Weight: 80 lbs (w/ stand)

- MAX no Load Speed: 5,000 rpm

- Dept of Cut at 90 Deg.: 3-one/two″

- Depth of Cut at 45 Deg.: two-1/2″

- MAX Rip Cut to Correct of Blade: 25″

- MAX Dado Cut Width: iii/4″

- Traditional sliding fence

- SawStop JSS-MCA

- Weight: 108 lbs (w/ stand)

- MAX no Load Speed: four,000 rpm

- Dept of Cut at 90 Deg.: 3-1/8″

- Depth of Cut at 45 Deg.: 2-1/8″

- MAX Rip Cut to Right of Bract: 25-i/ii″

- MAX Dado Cut Width: thirteen/sixteen″

- Traditional sliding fence

- Prophylactic: Mankind Sensing Applied science exclusive to SawStop

- SkilSaw SPT99-12

- Weight: 98 lbs (w/ stand)

- MAX no Load Speed: v,000 rpm

- Dept of Cut at ninety Deg.: 3-5/8″

- Depth of Cut at 45 Deg.: two-3/x″

- MAX Rip Cut to Right of Blade: xxx-i/2″

- MAX Dado Cut Width: "xiii/sixteen″, merely presently comes with an insert that just allows one/2

- Rack and pinion contend

Ane of the things nosotros looked at was the ease of assembly out of the box. We had the same person get together each of the saws and timed the assembly to see if there are any meaning differences betwixt the models. The associates fourth dimension for the saws ranged from 21 minutes to 48 minutes. While some stands required more than than twice the time, we felt the associates time was not a significant plenty factor to change someone'southward heed on which saw to buy.

We also did some testing of dust collection to see if there were whatever significant differences between the saws. We attached a Bosch dust extractor to each saw and measured the weight of grit collected for a fixed number of cuts. The bottom line is with a adept dust extractor fastened at that place was negligible difference between the saws.

Lastly, nosotros spent some fourth dimension evaluating the fences. Overwhelmingly the crew really likes the rack and pinion fences that DEWALT, Hitachi and SkilSaw have on their saws. Rack and pinion fences are quicker to suit, hold in place meliorate during cuts, and provide better accurateness.

Portable Jobsite Table Saw Precision & Accurateness

In the commercial construction business, nosotros typically buy a job site saw for each project and use it up during the course of an eighteen-calendar month chore. When these saws hit the site, they are unboxed, assembled and immediately put into use. We rip stacks and stacks of sheet goods with these saws and the tolerances of the cut materials are non very disquisitional. However, that example represents the portable saw use within our commercial crews' business.

What if a contractor uses their chore site saw for high quality built-ins or high tolerance finished cuts? In that case, saw accuracy is critical for that work. In this employ case, if the saw is immediately put into use, success depends upon the out-of-the-box accuracy from the manufacturer. The quality of the cuts and more chiefly the potential safety of the operator is going to be a function of the as-shipped accuracy of the saw from the manufacturer.

TBB compared the relative accuracy of the test saws every bit before long equally we assembled and set them up. How would the saws in the TBB Caput To Head examination compare to each other? We measured the manufactured tolerances and found out. Nosotros analyzed the information from the tests and ranked these saws for every bit-built accurateness.

What and How Nosotros Measured

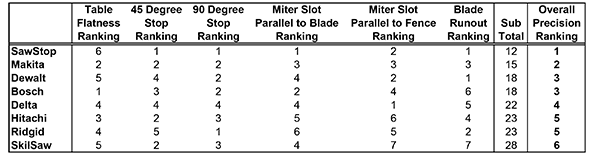

To appraise the manufactured accuracy of the eight saws, TBB looked at half-dozen areas to measure and compare: Table Flatness, Accuracy of 45 Deg. Stop, Accurateness of xc Deg. Stop, Blade Parallel to Miter Slot, Fence Parallel to Miter Slot, and Blade Runout.

Table Flatness

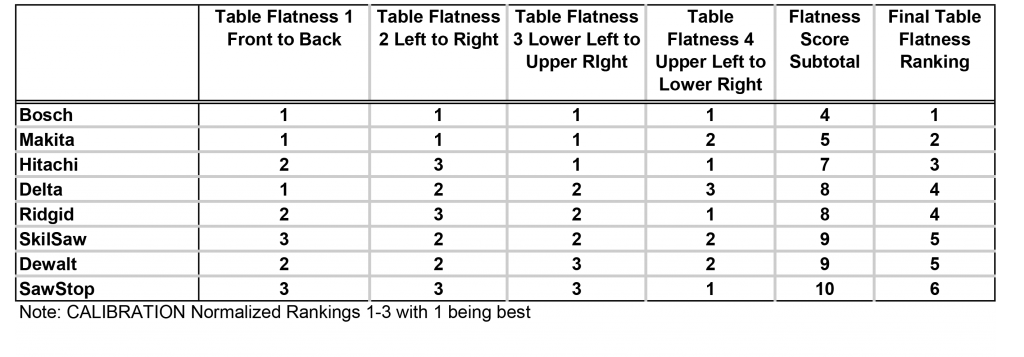

We evaluated the flatness of the table by measuring the flatness by placing the border of a precision ground flat bar across the table and placed feeler gauges in any gaps to measure whatever difference between the ground bar and the tabular array. TBB took measurements in 4 directions. Equally the operator faces the saw, we measured the flatness at the arbor from front-to-rear; we measured the left-to right flatness at the arbor; we measured the flatness from the upper left-to-lower correct table corners; and, finally, we measured the upper right-to-lower left flatness between the corners.

We compiled this set of data and created a ranked set up of results by assigning a 1-ii-3 rating to the relative values of the test measurements. And then we ranked the saws for overall as-manufactured table flatness. As a point of interest, a typical sheet of copy paper is approximately .004 inches thick. Flatness measurements varied from 0.0 to .09 inches.

All of the data for the table saw flatness can be plant here. The overall ranking of the table saw flatness is in the following table:

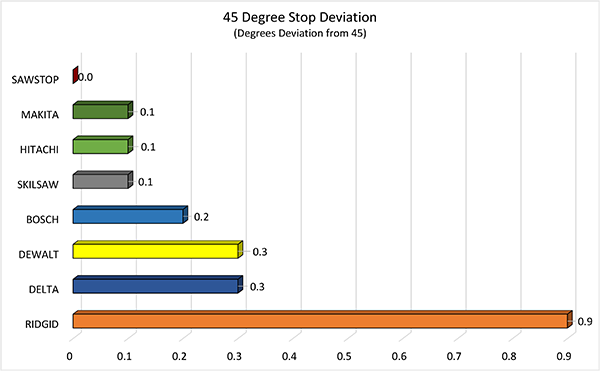

Accurateness of 45 Deg. Stop

Accurateness of 45 Deg. Stop

TBB measured the accurateness of the factory-set 45 degree stop by using a Wixey WR365 digital inclinometer. This device has an accuracy of 0.1 degree. We placed the Wixey gauge on the tabular array and calibrated the inclinometer to the table by zeroing out the guess. After that calibration, the measurements shown on the approximate give a issue that is relative to the saw table. Nosotros fastened the guess to the bract and used the saw mechanism to arrange the blade incline to the point at which the blade or trunnion hitting the factory-set 45 degree stop and recorded the measurement. TBB ran the test twice to ensure the repeatability of the measurement. In every instance, the issue came out to inside 0.one degree of the prior test.

Every bit you tin can see below most of the saws were fairly close to 45 degrees right out of the box, but you'll want to practice some calibration if yous plan on doing some finish piece of work. SawStop was perfect out of the box and Makita, Hitachi and SkilSaw were very close with only a 0.one degree deviation. Ridgid was near a full caste off from the 45 cease.

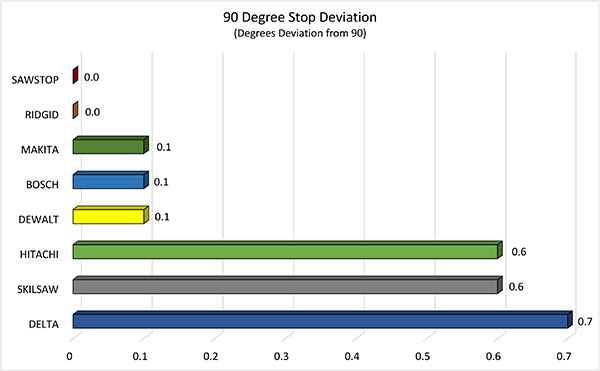

Accuracy of Vertical 90 Deg. Stop

TBB measured the accuracy of the factory-set 90 degree terminate past using a Wixey WR365 digital inclinometer. This device has an accuracy of 0.1 degree. We placed the Wixey gauge on the table and calibrated the inclinometer to the table by zeroing out the guess. Later on that calibration, the measurements give a issue that is relative to the saw table. We moved the bract to an estimate position of 70 degrees off vertical. TBB attached the gauge to the bract and used the saw mechanism to adjust the blade incline to the point at which the blade or trunnion hit the mill-set 90 degree vertical stop and recorded the measurement. TBB ran the test twice to ensure the repeatability of the measurement. In every example, the event came out to within 0.i degree of the prior examination.

The results are shown below for the accuracy of the ninety caste stop. For this evaluation both the SawStop and Ridgid were perfect at ninety degrees, Makita, Bosch and DEWALT were also only off by a small corporeality at 0.i degrees. The Hitachi, Delta and SkilSaw could apply some calibration.

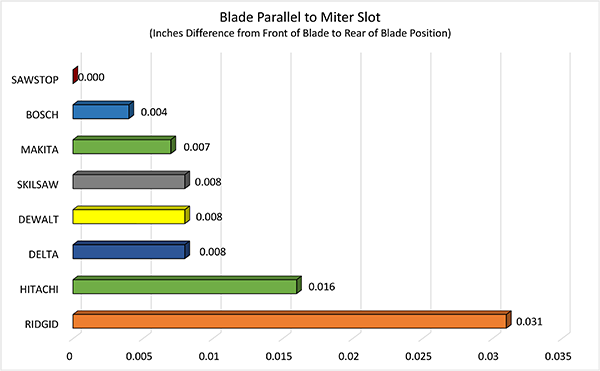

Blade Parallel to Miter Slot

TBB used an iGauging 35-125-four digital punch indicator to measure out the accuracy of the blade position to the table miter slot. This musical instrument has an accuracy of .0005 inches. Every bit office of the tabular array saw set-up, TBB installed a new Diablo blade in each saw and these never-earlier-used blades were used in the measurement test. To ensure that whatsoever wobble in the bract did non enter into the test results, TBB marked a single tooth equally the reference point for the measurement. The blade position was moved to the front of the saw to allow the iGauging dial indicator to hit the tooth immediately backside the carbide tooth, The iGauging dial indicator was calibrated and the indicator had a reading of zero.

Nosotros rotated the blade to the rear of the saw to enable the dial indicator to contact the same location of the same tooth behind the carbide portion. We positioned the dial indicator to the rear of the saw placed onto the bract and the reading recorded. If the bract and the miter slot were closer together at the rear of the saw, the dial indicator has a negative reading. If the bract and the miter slot were father apart at the rear of the saw, the punch indicator showed a positive reading.

The results for the bract parallel to the miter slot are shown below. Again the SawStop had a perfect reading right out of the box and the Ridgid needs some extra calibration in order to become the bract more parallel to the miter slot.

Saw Fence Parallel to Miter Slot

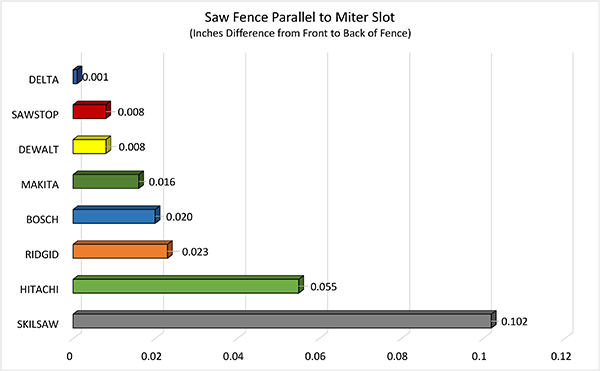

The accuracy and safety of whatever given saw is dependent upon the blade being parallel to the rip fence. Since nosotros tested the amount of divergence in parallelism between the saw bract and the miter slot in the previous test, nosotros demand only to encounter if the miter slot is parallel to the rip fence to run across if the saw has a parallel relationship between the blade and the rip fence.

TBB used the same iGauging 35-125-four digital dial indicator to measure the accuracy of the as-delivered factory fence to the table miter slot. Nosotros started by placing the fence in a locked position most 1" away from the blade on the opposite side from the miter slot. Nosotros adjusted the throw of the dial indicator so that we took the readings on the indicator, every bit before, in the center of the indicator's range of move.

We calibrated the iGauging punch indicator to a zero reading at the operator's end of the rip fence so that we started out with a reading of zero. Next, we positioned the dial indicator to the rear of the saw placed onto the rip debate and took the reading.

If the argue and the miter slot were closer together at the rear of the saw, the punch indicator has a negative reading. If the bract and the miter slot were male parent apart at the rear of the saw, the dial indicator showed a positive reading. A negative reading meant that the materials existence cut might be subject to being pinched and a kick dorsum more probable to occur.

Remembering that a sheet of paper is approximately 0.004″ thick, the results evidence that the Hitachi and Skilsaw manufacturing plant settings demand some adjustment for amend accuracy.

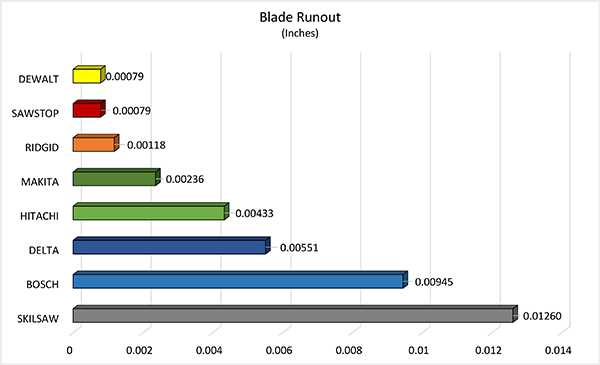

Blade Runout

Blade Runout

I term you may hear when reading almost table saw accuracy is bract runout. Runout is a term that describes whether or how much the outside edge of a saw blade wobbles while being held by the motor shaft. Sometimes, operators measure runout by using a saw blade. In that case, the very utilize of a saw blade presumes that the specific bract is perfect or nearly perfect in its flatness. Using a saw blade that has whatsoever warping volition not give a clear indication of blade runout.

To ensure that our runout measurements were authentic, TBB used a Freud scale plate. Freud manufactures this ground stainless steel plate to a tolerance of ± .0005 inches in flatness across the plate. While TBB does not have a means to measure out the accuracy of this specification, we did put this calibration plate on summit of a polished granite calibration table and could non smooth a light nether any portion of the plate or slip the 0.001 feeler gauge under the edge.

Nosotros used the Freud scale plate on each of the test saws to mensurate runout. Nosotros removed the new Diablo blade, installed the calibration plate, and raised the trunnion to its maximum vertical aligning. Before measuring the runout, we placed a black mark on the scale plate to give a consistent starting position for the runout test. The aforementioned iGauging punch indicator provided the test measurements, only this time, the units were set to read out in mm. TBB noticed that in the initial saws, the movements were sufficiently modest to need the smaller metric units.

TBB placed the dial indicator on the starting position of the calibration disk and calibrated that position on the dial indicator to a reading of zero. We were very careful to rotate the calibration plate past using the outside rim so as not to impart whatever side-to-side force on the plate that might introduce errors into the measurements.

While we rotated the plate, we recorded the maximum reading on the dial indicator. We validated each maximum reading past running the test for a second time and noting that the readings were consequent. TBB also noted that as nosotros performed these tests on all 8 saws, the maximum readings occurred at different parts of the plate along its rotation. Because the max readings were in unlike and discrete parts of the calibration plate, TBB had a very high level of confidence in the flatness of the calibration plate, itself.

As yous can see in a higher place the runout ranges from 0.00079 for the DEWALT and SawStop all the way upwards to 0.0126 for the SkilSaw. Typically values beneath 0.005″ are considered very skilful. Both the Bosch and SkilSaw are in a range that needs further evaluation especially if the saw is to be used for finish piece of work.

Precision Summary – Winner SawStop JSS-MCA

From the data of the six private tests in a higher place, nosotros compiled a summary ranking for the overall winner of the as-built accurateness. The ranking for the summary follows:

The winner for the equally-built precision and accuracy is SawStop, followed by Makita in 2d and Bosch and DEWALT tied for third.

We took the time to measure the as-built accuracy of these table saws. Why?

As we said in the beginning of this section, many of these saws volition be used, right out of the box, for rough cut materials and the fine accuracy may not matter so much in that application. If this is the case for a saw, the quality of the cuts and more than importantly, the potential safety of the operator is going to exist a role of the equally-shipped accuracy of the saw from the manufacturer. And so, TBB wanted to see how the various saws compared right out of the box. The results are in and, as a group, these eight saws measured up quite well for out-of-the-box accuracy.

It should exist noted that all of the saws were adjusted after the accurateness evaluation prior to the performance testing. With the exception of blade runout the other adjustments can be made to punch in the saws.

Portable Jobsite Table Saw Performance

For this portion of the testing and evaluation we used three different materials (3/4″ Ac Plywood, five/four Mahogany Decking, and 5/4 Pressure Treated Southern Yellow Pino Decking) while measuring the saw blade RPM, and the saw motor AMP draw. To compare the saws nosotros're looking for how much blade speed each saw has under load, and also how much the amp depict increases under load. Think about it like driving a auto, a more powerful car will not drop as much speed going up a loma and the engine won't work every bit hard.

Nosotros too measured the decibels during the test. Nosotros are including in our ergonomics section.

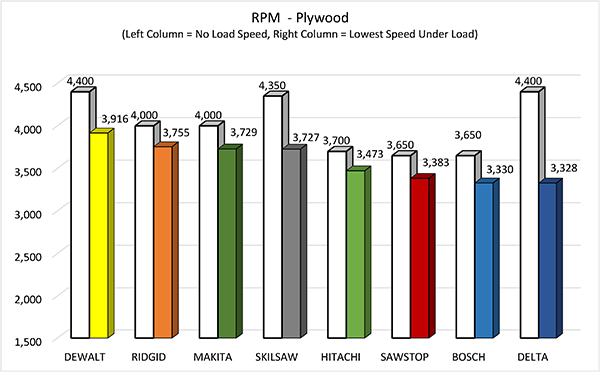

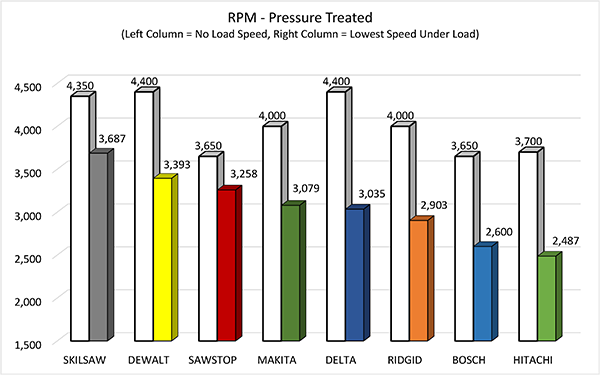

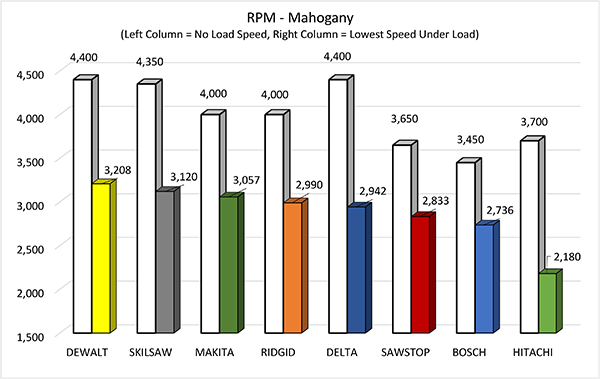

Bract Speed (RPM)

Bract Speed (RPM)

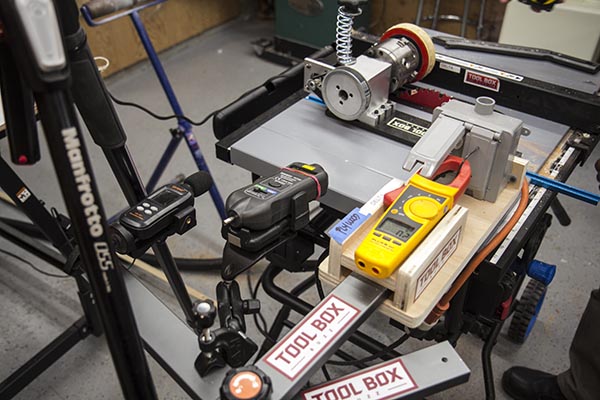

The beginning measurements nosotros looked at with the performance testing was bract speed cutting all three of the test materials. This tests gives usa a relative comparison of how much blade speed reduction the motors have under different loading conditions. In our opinion this gives u.s. an idea of how potent the motor/gear box combination is for each saw. For each exam we also recorded the "no-load" speed to capture the relative driblet in rpm in the blade speed while cutting wood. We used our as-measured no-load speeds instead of the published values from the manufacturers.

In order to measure the blade speed we used a digital light amplification by stimulated emission of radiation non-contact tachometer. A piece of reflective tape was adhered to each saw blade just behind the carbide tooth, so that the record would be but higher up the peak of the forest cutting surface, allowing us to capture the bract speed during the cuts. We used a ability-feeder to ensure that all the material was pushed through each saw at the aforementioned feed charge per unit. In the photo above you tin run across our test prepare-upward with the ability feeder, a decibel meter to the left, the digital tachometer in the center, and the amp meter on the right. If you expect really closely at the saw blade, the piece of reflective tape is to the left side of the blade near the ability feeder.

Above are the results for RPM Blade Speed while cutting 3/four″ plywood. In the left column is the no-load blade speed and the right column is the lowest recorded blade speed during the cut. The drib in blade speed is fairly modest ranging from 6% for Hitachi and Ridgid, seven% for Makita and SawStop, 9% Bosch, xi% DEWALT, xiv% SkilSaw, and 24% for the Delta.

In the adjacent test we measured blade speed cutting 2x pressure treated Southern Yellow Pine decking. In this test the lowest blade speed drop was eleven% for the SawStop, 15% SkilSaw, 23% DEWALT and Makita, 27% Ridgid, 29% Bosch, 31% Delta, and 33% for Hitachi.

The last test was using v/4 Mahogany Decking. This was an even more extreme exam with the everyman bract speed driblet going to SawStop at 22%, 24% Makita, 25% Bosch and Ridgid, 27% DEWALT, 28% SkilSaw, 33% Delta and 41% Hitachi.

Saw Blade Speed (RPM) Summary: The table saw with the lowest average driblet in bract speed for each of the tests we performed was the SawStop. Coming in second place was the Makita followed by Ridgid in third, Bosch and DEWALT in fourth, SkilSaw in 5th, Hitachi in sixth, and Delta in 7th place.

Motor AMP Draw

Motor AMP Draw

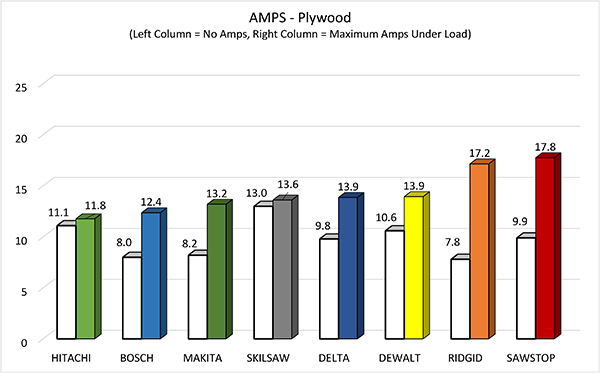

Another indication of how hard a table saw is working is monitoring the amperage (AMP) draw under loading conditions. We measured the amp draw for each saw using all three materials again at the same time we were recording RPMs. The start graph beneath shows the amp depict for each saw cutting plywood compared to the no-load amp describe. The white bar on the left indicates the no load amps and the colored bar on the correct shows the maximum amp depict during the cut.

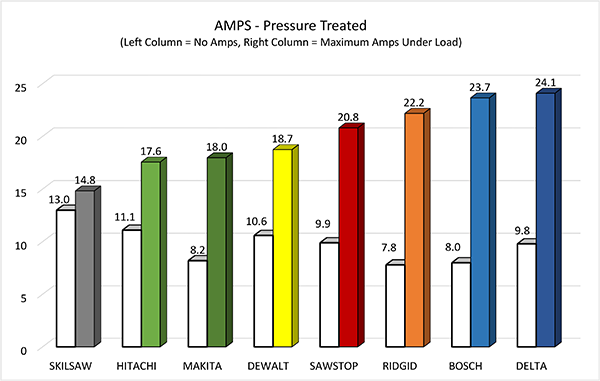

The next graph includes the results from the pressure treated framing lumber.

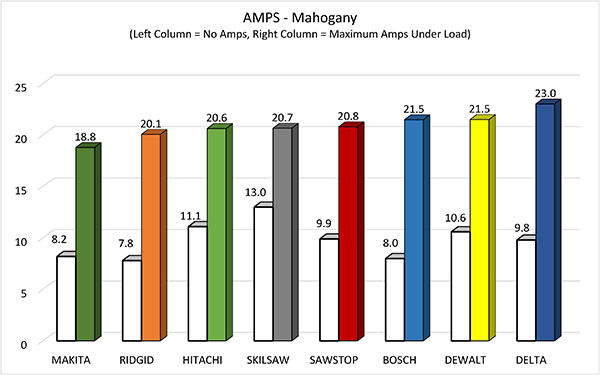

The next graph includes the results from the 5/4 Mahogany decking.

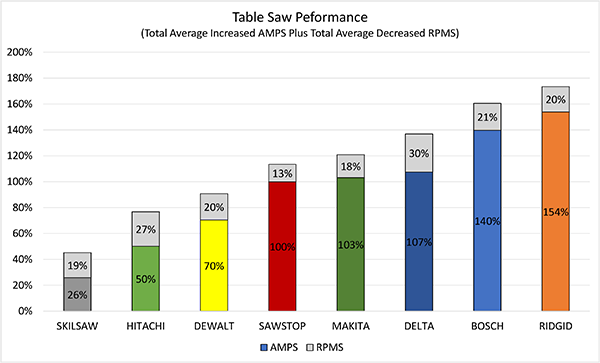

Functioning Summary – Winner Skilsaw SPT99-12

Nosotros took all of the information from the RPM and AMP measurements and added them to come up with the last performance rankings. For each saw we added upwards the full percent subtract in RPM's (for each material blazon) and added that to the total percent increase in AMP's (for each cloth type). This gives us a relative comparison of each saw over all 6 sets of information.

The best overall performance in our testing was the Skilsaw SPT99-12. The Skilsaw was described by many of the TBB crew as a fauna and the data reinforces that. Regardless of the type of fabric the Skilsaw SPT99-12 offered the everyman drib in RPM's and the everyman increase in AMP depict. Following in second place is the Hitachi C10RJ and the DEWALT DWE7491RS in third place.

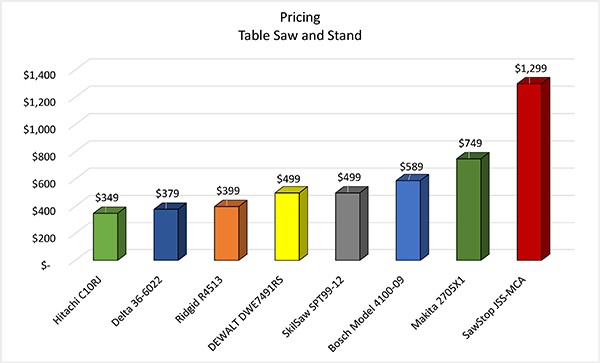

Portable Jobsite Table Saw Toll

Beneath we've included the current pricing (at the time of publishing this article). Pricing includes the price of the stand up and ranges from a low of $349 for the Hitachi to a high of $1,299 for the SawStop. The everyman toll isn't always the all-time in our stance, we're looking for the all-time value. The Hitachi is an incredible deal at $349 and our meridian choice for cost and value for a saw that has lots of power, a rack & pinion fence, and a solid stand.

Another actually nice value is the Ridgid that'south currently selling for $399 including the stand. Lastly, information technology's difficult to ignore the $499 cost tag on the DEWALT which is a great contractor grade saw with great features, a great fence, and a actually proficient stand.

Price Summary – Winner Hitachi C10RJ

Buy Now From Our Sponsored Retailers

Other Options

Portable Jobsite Tabular array Saw Ergonomics

Ergonomics is the science of designing and producing tools that improve a worker'due south efficiency while reducing discomfort, fatigue, and risk of injury. Ergonomically enhanced tools tin include helpful features such every bit angled handles, riving knives, safety switches, and not-slip coatings. Whether you're shopping for ergonomic tools or just trying to select the right one for the chore from an existing collection, the key things to consider are whether or not the tool eases your piece of work and prevents you from straining in means that could lead to injury. Ergonomic guidelines in tool design tin help maximize human performance on the task by making the job easier for the worker, improving safety and decreasing injuries.

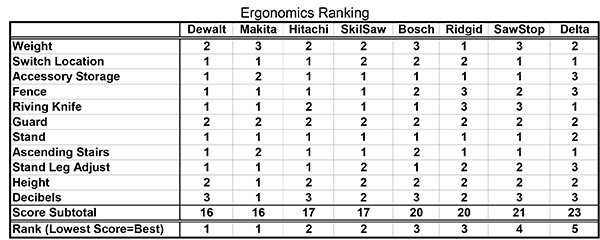

For this ergonomic section, we considered the following factors, rating them 1 thru three. [one being best]

- Weight (Tool and Stand up)

- Power Switch location

- Accessory Storage

- Debate

- Adjustments of Riving Knife

- Baby-sit

- Stand

- Ascending Stairs

- Stand Leg Suit

- Pinnacle

- Decibels

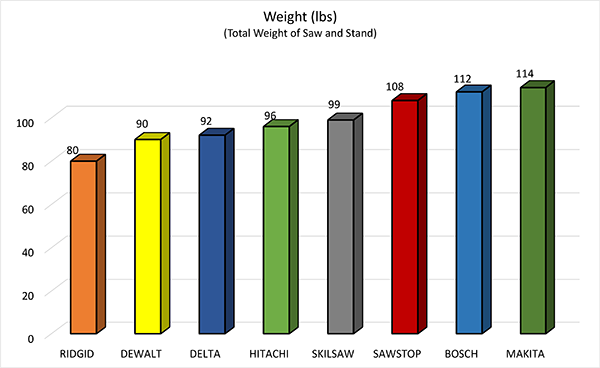

Below is a graph showing the weights of all the tabular array saws including their stands. The saws/stands range from 80 lbs with the Ridgid up to 114 lbs for the Makita.

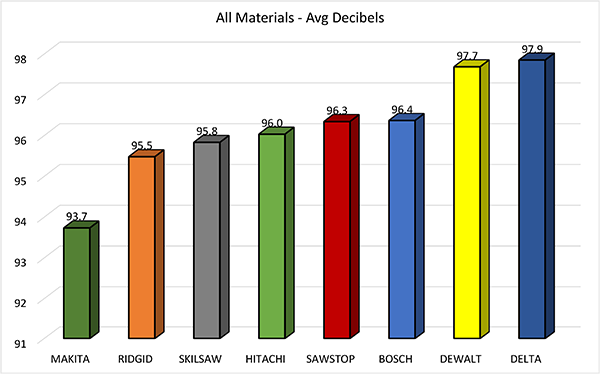

Beneath is a graph showing the average measured decibels for the saws (for each of the materials we tested). Equally you can run into the saws range from 93.vii db to 97.9 db. OSHA allows 8 hours of exposure for up to 90 db, from 95 db up the exposure limits first dropping quickly starting at iv hrs for 95 db so clearly these saws all need hearing protection. The Makita was given the best score of one as information technology was considerably quieter than the remaining. DEWALT and Delta were ranked worse with a score of 3, while the remaining were ranked as a ii.

Our TBB crew all helped rank each of the table saws for the ergonomics categories that we defined. Below is a table showing the ranking for each category and the final ranking. An interesting notation about the stand height. The crew felt they were all decent heights but the Makita offers several heights which is a actually nice feature!

Ergonomics Summary – Winners DEWALT DWE7491RS and Makita 2705X1

The DEWALT and Makita finished in first for our ergonomic rankings followed by a tie for second between Hitachi and Skilsaw and a tie for third place by Bosch and Ridgid. Both the DEWALT and Makita built their saw with the professional person contractor in heed. Overall the unabridged crew really likes the saws with a rack-and-pinion fence arrangement and the large wheels on the Skilsaw were also a big favorite.

Best Portable Jobsite Tabular array Saw – Winner Hitachi C10RJ

Choosing the best portable jobsite table saw wasn't an easy task but we're confident we've washed a thorough evaluation. In a very close race for the best table saw Hitachi beat out out the DEWALT which came in 2nd place followed by Skilsaw in tertiary and Makita in 4th. It'southward very interesting that the Hitachi and DEWALT look extremely like. Hitachi edged out the DEWALT in performance and price resulting in the last scores. Skilsaw crush Makita for the tertiary identify only slightly and that issue is really a function of pricing.

It'southward interesting to note that if pricing was taken out of this evaluation the ranking would have been: DEWALT in commencement, Makita in 2d, Hitachi, Skilsaw and SawStop tied for third, Bosch in fourth, Delta in fifth and Ridgid in sixth place. Simply at the end of the day price is certainly a factor. What we didn't do in our evaluation is any long term testing to await at immovability which ultimately could affect your buy decision as well.

We actually should point out a big deal here and that's the SawStop. It'due south hard to put a price on safety and while the SawStop costs more 3 times what the Hitachi costs it does offering safety that no other saw in examination tin offering. For those that can afford the additional cost that feature alone may tip the scales for you. Regardless of price SawStop came in 5th identify for the categories nosotros evaluated.

Concluding Thoughts

These tests and evaluations are very hard, have a lot of time, and ultimately limited in scope as we're not a professional testing company and nosotros've got limited fourth dimension to evaluate the tools. Nosotros cannot practice longer term testing that would shed light on durability and we can't possibly test every application that yous might use of one of these saws for. Even so, we feel comfy that all the table saws in this Head-to-Head are good saws and our testing helps bring to calorie-free pros and cons for each saw.

Ultimately everyone needs to choose a tool based on their specific needs, uses, and budget. With all the data above we're very confident that all of you lot tin can brand a amend educated conclusion when you buy your next portable jobsite table saw.

Buy Now From Our Sponsored Retailers

Other Options

Best Portable Jobsite Table Saw Head-2-Head Video Review

Source: https://www.toolboxbuzz.com/head-to-head/best-portable-jobsite-table-saw-head-to-head/

Accurateness of 45 Deg. Stop

Accurateness of 45 Deg. Stop Blade Runout

Blade Runout Bract Speed (RPM)

Bract Speed (RPM) Motor AMP Draw

Motor AMP Draw

Post a Comment for "10 in Table Saw With Wheeled Stand Model #rts31 Review"